Automate battery management system (BMS) test with a digital twin EDN logo JULY 11, 2024

A battery management system (BMS) monitors and controls batteries in vehicles such as more-electric aircraft and electric cars. It needs to undergo rigorous tests under nominal and extreme conditions to prove its quality and integrity.

Testing with emulated battery cells is beneficial because one can safely test all kinds of conditions quickly and repeatedly without risking precious hardware. This type of hardware-in-the-loop testing simplifies quality assurance and keeps up with the pace of innovation.

Batteries are crucial for electrifying drive trains in vehicles or actuators in aircraft and ships, and BMS is a vital piece of the puzzle for controlling and monitoring the battery pack. The BMS ensures safe battery operation, effective use of its capacity, and long service life.

Advertisement

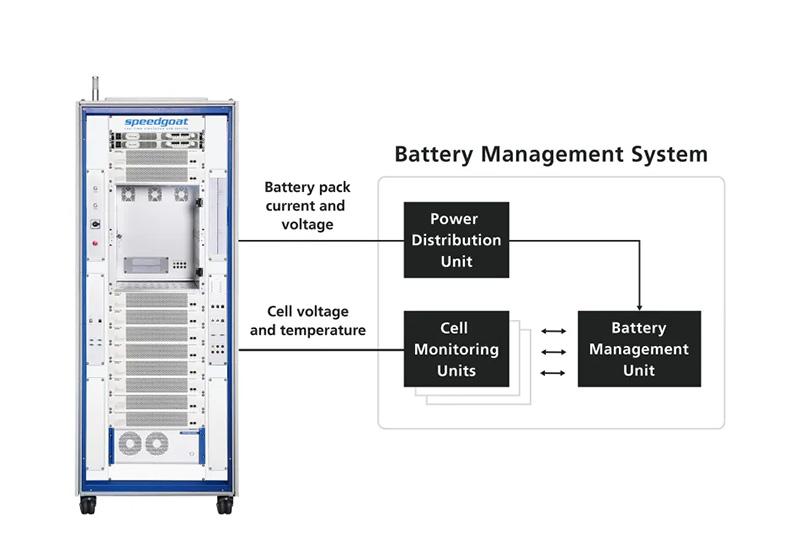

BMS is used in cars, aircraft, energy storage systems, and consumer electronics, among other things. It typically comprises a battery management unit (BMU), a cell monitoring unit (CMU), and a power distribution unit (PDU).

Figure 1 BMS ensures safe battery operation, effective use of its capacity, and long service life. Source: Speedgoat GmbH

The battery management unit is the main controller; being connected to the cell monitoring and power distribution unit, it monitors the overall state of charge (SOC) as well as cell voltages and cell temperature information. The cell monitoring unit is linked to the battery cells; these modules form battery packs—each has a CMU to regulate the charge and discharge of individual cells, temperature, and voltage.

The power distribution unit is connected to all components that draw power from the pack or feed it back in—in an electric vehicle (EV), this could be the charging system and the motor, for example.

Testing battery management system (BMS)

Rigorous testing ensures that BMS fulfills its requirements, such as optimally distributing the current between the cells during charging. The BMS is checked in the nominal range and extreme situations, for example, when cells overheat, a signal fails, or a short circuit occurs. This way, it’s possible to test how BMS reacts in such cases and ensure correct functioning.

Testing BMS comes with various challenges and is a complex task. The BMS houses various controllers, processes signals from distributed sensors and is linked to numerous systems such as the powertrain. Testing all functionalities, configurations, and states is a lot of effort, which is scarcely achievable with real batteries.

As batteries age, it’s also vital to reproduce conditions repeatedly to test critical algorithms such as cell balancing and state of charge or state of health (SoH) estimation. In addition, different teams are usually responsible for the individual components during development, and their engineers are not always available.

Batteries, BMS and infrastructures are also evolving, so the providers of the systems must keep up with this and react swiftly to new requirements. Finally, testing with real hardware can be dangerous; in the worst case, batteries could explode due to over-voltages or extreme temperatures.

BMS testing with digital twins

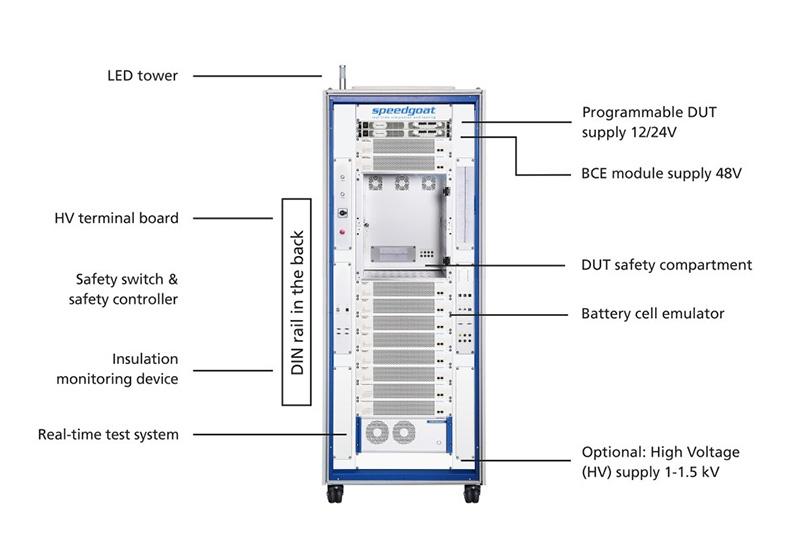

These challenges can be solved using a battery’s digital twin. A battery cell emulator can mimic the behavior of the battery by precisely emulating voltages, current levels, and temperatures. It can represent various battery pack architectures and integrate seamlessly with standard test frameworks.

Figure 2 The Battery Cell Emulator (BCE) mimics the behavior of the battery by precisely emulating voltages, current levels, and temperatures. Source: Speedgoat GmbH

Taking into account battery technology and chemistry, age, and operating temperatures, the battery cell emulator can accommodate all kinds of battery models. Tests can be conducted swiftly and safely in regular operational conditions and under faulty conditions.

The same communication protocols are used when interfacing with the actual batteries. Testing with a digital twin also facilitates testing the rest of the system, such as power distribution and charging components, motor drives and fuel cells.

It must be possible to reproduce the same conditions in tests to check the controllers’ behavior reliably. In addition, a flexible test infrastructure that allows engineers to continuously test functionalities and changes in the development process to fulfill novel requirements is essential. Furthermore, testing many scenarios, including complexities, is crucial to achieve complete test coverage.

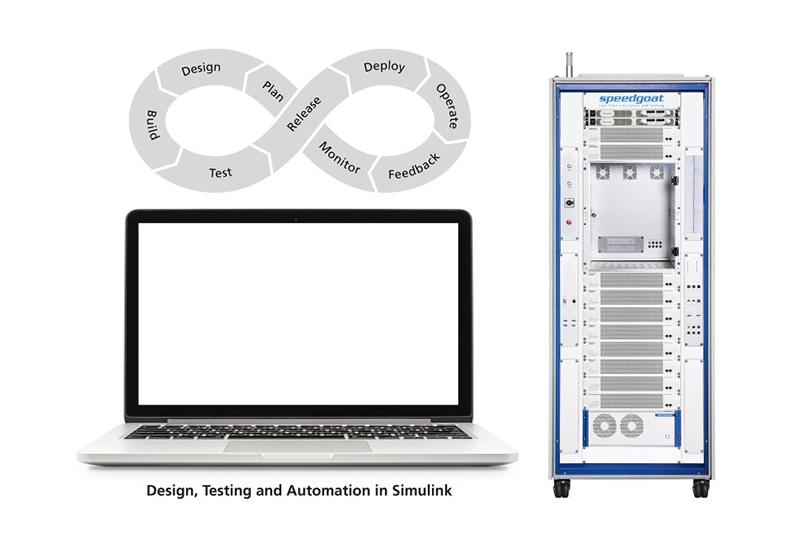

Test cases are usually defined and tracked in software. Automated test procedures are important for repeating tests and comparing results efficiently. Requirements are typically managed in Simulink’s dedicated toolboxes, such as Simulink Test, or ASAM XIL-compatible third-party software tools.

The advantages of digital testing

For testing the BMS controller and its interactions with various components, the behavior of the actual battery can be precisely emulated with a digital twin. Many insights are available early, allowing the engineers to adjust designs and functions when changes are still easy to implement. Also, a battery’s digital twin does justice to fast-changing trends—it’s more flexible than hardware. It can be configured seamlessly to adapt to new conditions.

Additionally, with the digital twin, components can be tested before assembly. This saves time, and complications or design errors can be found early in the development process, improving the quality and speed of development. Likewise, development and testing costs can be saved because corrections are made at early stages rather than late in development. Finally, risk-free testing of the BMS is possible in extreme events such as collisions, faulty cells, or over-voltage.

Therefore, testing with digital twins of batteries is suitable for engineers who test and validate battery management systems and aim for a continuous and automated workflow. An attractive feature for users is that they can carry out all tests in one software environment (Simulink).

The battery model is developed in Simulink. Afterward, the tests can be performed using the same model with the hardware in the background. The flexible test infrastructure and toolboxes enable continuous, automated testing along the defined requirements.

Figure 3 All automated BMS tests can be performed in a single software environment (Simulink). Source: Speedgoat GmbH

As battery management systems ensure safe battery operation, they need to be thoroughly tested. A digital twin allows engineers to precisely emulate BMS batteries and to safely test all kinds of conditions quickly and repeatedly without risking damaging hardware. Such a test system is suitable for engineers in various industries who need to conduct BMS tests continuously and automatically