How to Design Reliable Next-Gen Automotive Control Electronics

As automotive vehicle electrification continues to increase and add more functions, the capability of the electronic control architecture must also increase to manage the vehicle's operation efficiently, responsively, and safely. The control architecture is evolving from a simple distributed control architecture to a zonal control system where zonal control units manage multiple electronic control units (ECUs) near each other.

The zonal control units manage ECUs near each other, simplifying wiring and reducing vehicle weight. The main communication protocol for zonal control is automotive Ethernet. The zonal control unit becomes the critically important control unit for the entire vehicle, and it must be a robust and reliable device. (For more on the evolution of control schemes, see the sidebar “The Evolution of Automotive Control Architectures” at the end of this article.)

Protection from Electrical Hazards

Protecting the zonal control unit from electrical hazards such as overcurrent, transient voltages, and electrostatic discharge (ESD) is essential for its reliable operation in the automotive environment. In addition, protection for the Ethernet lines is critical for ensuring reliable vehicle performance through uninterrupted functioning of the communication bus and uncorrupted data transmission.

This article provides designers with valuable information on components that can protect the circuits in the zonal controller from electrical hazards. Protecting communication data lines from disruption due to electrical harm is of particular importance, and designers will learn about specialized components that will protect their communication lines. This information will help designers develop high-reliability automotive electronics.

Zonal Control Unit (ZCU) Description

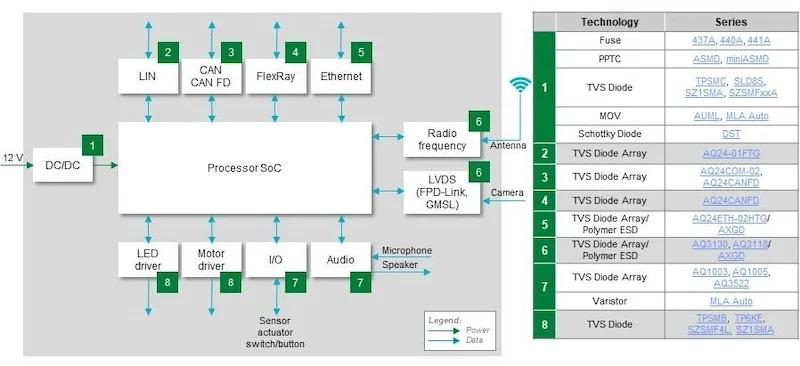

The ZCU interfaces with all types of devices in its zone of control. Thus, it can use many different types of communication protocols to interface with a wide range of devices. Figure 1 illustrates the circuit blocks of a ZCU. Hazards that could damage the ZCU include overcurrent conditions, transient voltages, and particularly ESD.

Figure 1. Zonal control unit block diagram

Protecting the DC-DC Converter

The DC-DC Converter down-converts the 12 V input to digital logic voltage levels. Since the DC-DC Converter is the power entrant to the ZCU, preventing damage from an overcurrent condition and keeping voltage transients out of the circuit is essential for reliable operation.

Either a one-time fuse or a resettable fuse can provide overcurrent protection. Consider a fast-acting, one-time fuse. Versions can open in less than 5 seconds to a 250% overload. A wide temperature range is essential for automotive applications. Fuses rated from -55°C to +150°C are available. To save space, select a surface mount fuse, which can be in a small 1206 package. Also, choose AEC-Q200-qualified components for automotive applications whenever possible.

A polymer positive temperature coefficient (PPTC) resettable fuse is an alternative to the one-time fuse. A benefit over a single-shot fuse is that PPTCs are resettable. Once the overcurrent condition has cleared, the PPTC will return to a low-resistance state and reconnect the power to the circuit. AEC-Q200 versions are available and come in space-saving surface-mount packages.

Metal Oxide Varistors and TVS Diodes

For voltage transient protection, particularly against inductive transients such as inductive energy discharges, either a metal oxide varistor (MOV) or a transient suppressor diode (TVS) can safely absorb their energy.

MOVs:

-

Can absorb load dump energy up to 25 J as required by SAE specification J1113

-

Have a wide operating temperature range from -40°C to +125°C

-

Are AEC-Q200 compliant.

The alternative component, models of TVS diodes, offer:

-

ESD protection to strikes as large as 30 kV in accordance with IEC 61000-4-2

-

Absorption of peak power pulses up to 1500 W or surge currents up to 200 A

-

Response times from under 1 ps to under 1 ns

-

A wide operating temperature range of -65°C to + 150°C

-

Unidirectional or bi-directional models

-

Surface mount packaging

-

AEC-Q101 qualification.

Protecting the DC-DC Converter from overcurrent and transient voltage surges prevents these hazardous conditions from propagating to downstream circuits, ensuring the ZCU processor is shielded from damaging energy.

Protecting the ZCU Interface Circuits

In the high noise and high transient automotive environment, all the ZCU circuits that interface with external devices via a communication protocol or a control driver need protection from ESD. Littelfuse for example, has an extensive portfolio of ESD diodes and polymer ESD components to address the unique requirements for the various communication protocols.

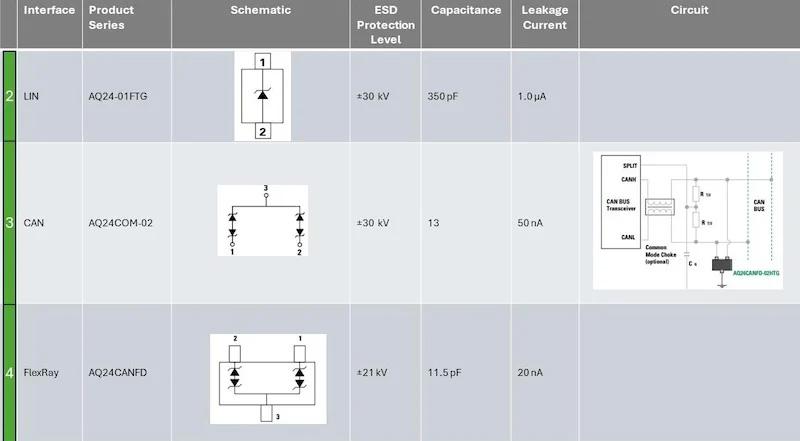

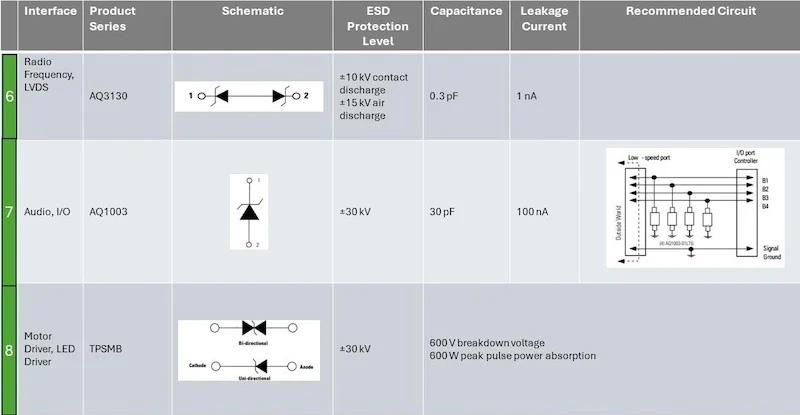

The protection components are optimized to minimize signal distortion while at the same time providing robust ESD protection. The two tables, Tables 1 and 2, describe recommended ESD diodes for the different interfaces. Schematics show the different configurations, and the tables list a few parameters.

The ESD Diode recommended for the Radio Frequency circuit has the lowest capacitance and leakage current to provide ESD protection and minimize signal distortion for low-level RF signals. For the CAN and the I/O interfaces, example circuits show the implementation of the TVS diodes.

Table 1. Recommended ESD Diodes for LIN, CAN, and FlexRay interface ESD protection. (Click image to enlarge)

Table 2. Recommended ESD and TVS Diodes for RF, LVDS, Audio, I/O, LED, and Motor interface ESD protection. (Click image to enlarge)

Protecting the Automotive Ethernet Physical Layer

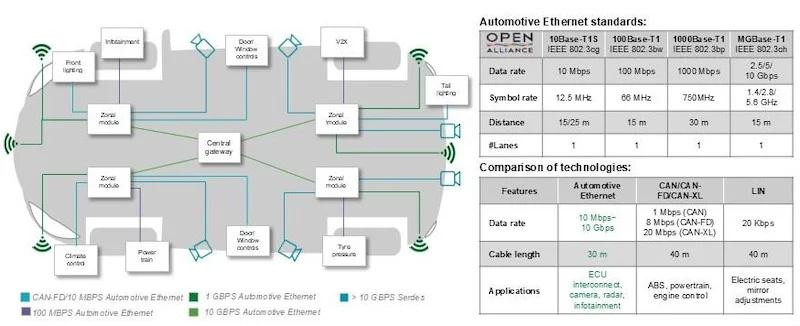

Automotive Ethernet has become the primary interface for communication in the zonal control architecture. Automotive Ethernet has the advantage of high data transmission rates that can achieve 10 Gb/s, a much higher data rate than the other automotive communication protocols.

Today, the typical data rates are 100 Mb/s and 1 Gb/s. In addition, Ethernet uses a lightweight, two-wire twisted pair. It has robust error-checking mechanisms to withstand the harsh automotive environment for electronics. Ethernet is also scalable which enables the protocol to accommodate new requirements.

The impetus behind implementing Ethernet in the zonal architecture is the OPEN Alliance SIG, a non-profit industry alliance of mainly automotive industry and technology providers formed to promote the wide-scale adoption of Ethernet connectivity as the standard in automotive networking applications.

OPEN Alliance Requirements

The top table in Figure 2 lists multiple “flavors” defined by the OPEN Alliance. The lower table compares automotive Ethernet with two other automotive communication protocols, CAN and LIN.

Figure 2. Zonal communication structure and automotive Ethernet compared with other automotive communication protocols

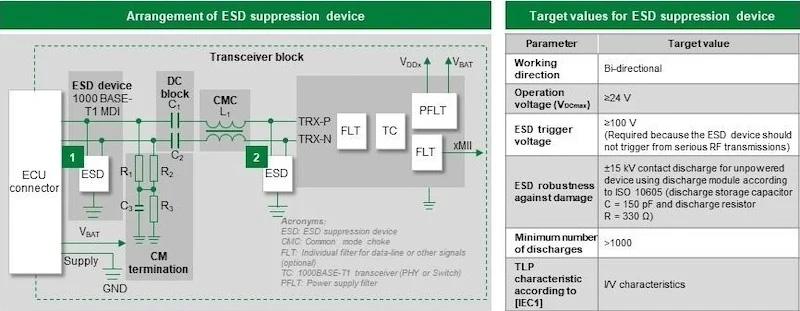

The OPEN Alliance has defined specific requirements for protecting automotive Ethernet circuits from ESD. Figure 3 shows an Ethernet transceiver circuit with the ESD protection device’s recommended location called “1”. The adjacent table lists the OPEN Alliance’s requirements for an ESD suppression device. (The ESD protection “2” has no relation to the OPEN Alliance SIG.)

Figure 3. OPEN Alliance SIG recommendation for ESD suppression implementation

Littelfuse has developed numerous ESD suppression components for Ethernet protection, including one that specifically complies with the OPEN Alliance requirements. In addition to meeting the requirements of the OPEN Alliance for an ESD suppression device, the Littelfuse solution has low capacitance to minimize distortion of the Ethernet signals and low leakage to minimize energy consumption.

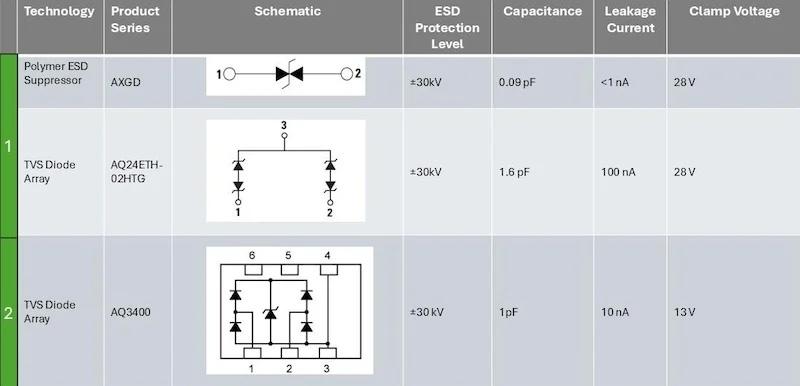

Table 3 contains details on three options for Ethernet protection. The Polymer ESD suppressor has the advantage of the lowest capacitance and the lowest leakage current. The two TVS diode arrays protect two data lines in one package.

Table 3. ESD protection solutions that are applicable to Automotive Ethernet. (Click image to enlarge)

All three components exceed the recommended ESD protection level called out by the OPEN Alliance SIG. They are all AEC-Q qualified; the Polymer ESD Suppressor to AEC-Q200 and the ESD Diodes to AEC-Q101. The AQ24ETH-02HTG is also certified to the OPEN Alliance specification.

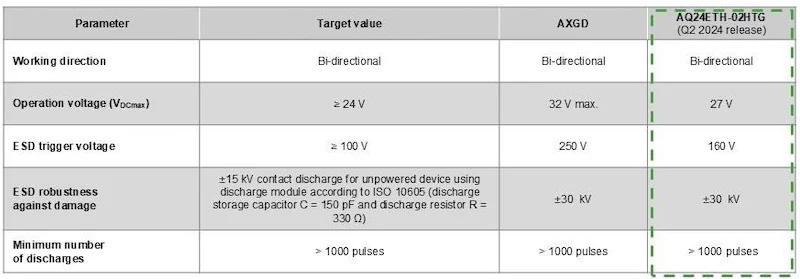

Table 4 compares the Polymer ESD Suppressor and one of the Diode Arrays with the OPEN Alliance requirements. Both exceed the OPEN Alliance’s ESD robustness against damage level. The OPEN Alliance has approved the AQ24ETH-02HTG TVS Diode Array to protect 100Base-T1 and 1000Base-T1 transceivers from ESD strikes.

Table 4. ESD suppression components comparison with OPEN Alliance requirements

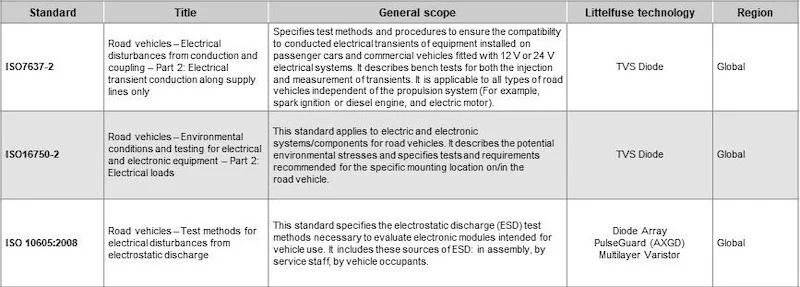

Applicable Automotive Transient Test Standards

Table 5 lists the standards that apply to methods and testing for transient protection and includes recommended technology solutions. Automotive designers should verify that their products comply with these standards.

Table 5. International standards for transient protection

Selecting the Right Components for ZCU Reliability

The circuitry in a zonal control unit needs to withstand the electrical hazards inherent in the severe automotive environment. This article offers designers recommendations and options for components protecting the ZCU and all its interfaces.

Designers should optimize their design process by identifying protection components early, as well as consulting with a component manufacturer's application engineers to save development time and compliance costs. The application engineers can help with the following:

-

Selection of cost-effective protection components

-

Knowledge on compliance to the applicable safety standards

-

Pre-compliance testing (performed by some manufacturers such as Littelfuse) to avoid compliance failure and save on delays and costs for multiple compliance test cycles.

All the Littelfuse components presented are AEC-Q101 and AEC-Q200 qualified. Using these recommended components will ensure reliable and robust ZCUs with ESD-resistant interfaces.

Download the Automotive Electronics Applications Guide to learn more about evaluating these protection recommendations, courtesy of Littelfuse.

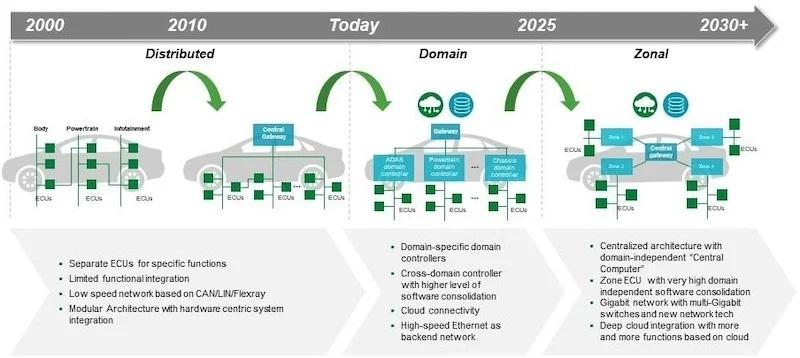

Sidebar: The Evolution of Automotive Control Architectures

As automobile electrification continues to grow, automotive architectures will need to adapt as well. Today, high-end automobiles may have as many as 150 electronic control units (ECUs).

Features such as autonomous driving and vehicle-to-infrastructure communication will add more complexity and a significant number of ECUs. The growing number of ECUs overwhelms the simplified distributed control architecture in which each ECU communicates along the central gateway, creating bottlenecks.

To alleviate the demands on a distributed control structure, automotive designers developed a domain structure that combined common functions such as powertrain, braking, and lighting under a domain controller.

Figure A. Automotive control architectures have evolved from distributed, to domain, to zonal. Image used courtesy of McKinsey Report

The domain controllers perform local control allowing the central controller to concentrate on supervisory duties. However, the domain architecture can complicate wiring as common functions can be in distant locations in the vehicle.

Benefits of the Zonal Control Structure

A more advanced architecture under development is a zonal control structure that employs more sophisticated controllers known as zonal control units. These controllers manage all functions and features in a specific physical zone of the vehicle. Powerful zonal controllers allow more software-defined functionality. The benefits of zonal control include:

-

Reduces wiring complexity and the total amount of wiring that is required.

-

Allows greater modularity and scalability, including adding, modifying, or removing zones without affecting the functionality of the entire vehicle.

-

Faster and more efficient coordination between zones through a high-speed Ethernet communication network

-

Distributed processing power improves vehicle response times, energy efficiency, and redundancy, enabling a greater degree of safety.

To ensure the zonal control units remain operational in the harsh automotive environment, they need to be capable of withstanding various electrical hazards including, overcurrent conditions, overvoltage transients, and ESD. Appropriate protection components added to the circuitry are essential to ensure robust performance.

Except where otherwise indicated, all images used courtesy of Littelfuse

Technical References

ESD Standard

IEC 61000-4-2:2008. Electromagnetic compatibility (EMC) - Part 4-2: Testing and measurement techniques - Electrostatic discharge immunity test

Automotive Component Standards

AEC-Q101 (aecouncil.com). Failure Mechanism Based Stress Test Qualification for Discrete Semiconductors in Automotive Applications

STRESS TEST QUALIFICATION (aecouncil.com). AEC-Q200 Rev E Stress Test Qualification for Passive Components

Organizations

OPEN Alliance SIG (opensig.org) Driving industry standards for Ethernet connectivity and enabling the migration from multiple closed applications to an open, scalable Ethernet-based network.

ISO - International Organization for Standardization. Creating global standards for trusted goods and services

Marketing Reports

Automotive software and e/e architecture | McKinsey. Automotive software and electrical/electronic architecture: Implications for OEMs.

Industry Articles are a form of content that allows industry partners to share useful news, messages, and technology with All About Circuits readers in a way editorial content is not well suited to. All Industry Articles are subject to strict editorial guidelines with the intention of offering readers useful news, technical expertise, or stories. The viewpoints and opinions expressed in Industry Articles are those of the partner and not necessarily those of All About Circuits or its writers.